Blow molding is a method of producing hollow plastic pieces by shaping and connecting them. It can also be used to make glass bottles or other hollow objects. While injection molding and rotational molding are more precise methods of plastic molding, blow molding offers the advantage of high-volume capacity, efficiency, and relatively low costs. Read More…

No matter what your blow molding needs are Western Industries is ready to assist you. We believe in thinking outside the mold and using unique methods to come up with large-part blow molding solutions for our customers. We have access to state-of-the-art technology and over 100 years of combined experience serving a variety of industries. When you choose Western Industries, you have the Western...

With blow molding presses from 1 to 80 lbs., Iceberg Molding has the ability & resources for every step of your blow molding requirements - from a competitive part quote to part & product development support start to finish.

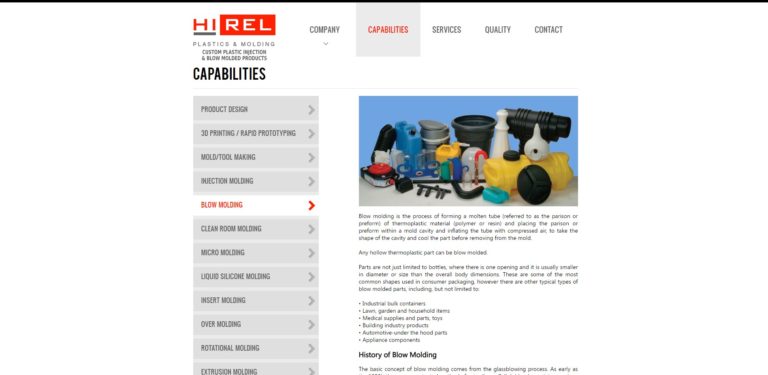

Founded in 1984, Hi-Rel Plastics & Molding, Inc. is a turn-key manufacturer who offers custom blow molding and custom plastic injection molding for a variety of industries. With more than 35 years of experience, our quality products are unparalleled. We process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we offer superior customer...

Depend on the custom blow molders since 1978. ACM Plastic Products offers complete blow molding capabilities, including many specialty services like insert molding, painting, foaming, assembly & packaging – just name it! New product development & short runs through high volume production, our seasoned professionals put quality & cost efficiency first. Call us today for honestly the best...

EXI-plast is a full-service provider of custom plastic moulding services, specializing in blow moulded solutions for customers worldwide across a wide variety of industries. With over 30 years of experience developing, producing, and finishing custom plastic products, we have also become a sustainability leader through the integration of postconsumer resins. With products ranging from less than...

Since 1952, SPI Group has provided custom blow molding for a diverse range of industries, such as agricultural, plumbing, electronics, and more. Our team can meet your needs with a variety of plastics, such as HDPE, ABS, polycarbonate, and TPE. Secondary operations and assembly services are also available. SPI is a leader in our industry due to our customer-oriented ability to deliver successful...

At Cado Company, we specialize in delivering high-quality blow molding solutions tailored to meet the unique needs of our clients. With years of experience in the industry, we have honed our expertise in producing durable, precise, and reliable blow-molded products.

At Western Case Incorporated, we focus on excellence in blow molding, producing custom plastic cases and components that are designed with precision and durability in mind. Our process allows us to create strong, lightweight products that combine functionality with consistent quality.

More Blow Moulding Companies

What is Blow Molding?

Blow molding is a specialized manufacturing process used to produce hollow plastic components, such as bottles, containers, tanks, and other packaging materials. This plastic forming technique relies on shaping and connecting molten thermoplastic materials inside a custom or standard mold using compressed air. While blow molding is widely associated with plastic production, it can also be adapted to create glass bottles and other hollow glass objects. Compared to other plastic molding processes like injection molding and rotational molding, blow molding offers significant advantages in terms of high-volume production capability, cost-effectiveness, and process efficiency, making it a preferred solution for industries requiring mass production of hollow plastic products.

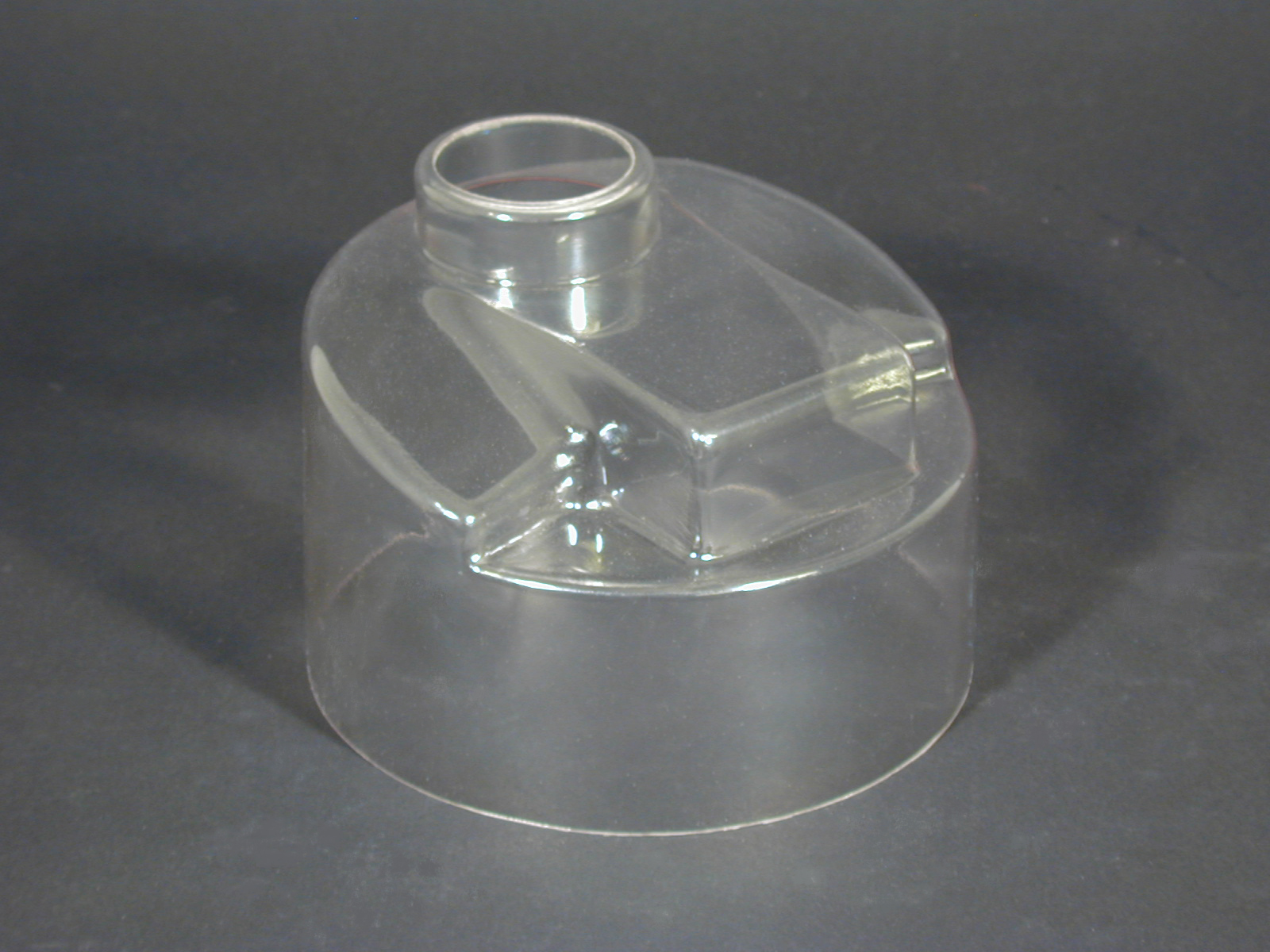

Blow molded products can be formed using standard die-cast cavities for common items, or through custom blow molding to meet specific design and performance requirements for specialized applications. This versatility makes blow molding the optimal choice for manufacturing hollow plastic parts with complex geometries, superior strength, and reliable durability. Industries such as packaging, automotive, medical, consumer goods, and industrial equipment benefit from the unique properties and scalable production offered by blow molding. If you are researching the advantages of blow molded plastics, considering custom blow molding solutions, or comparing manufacturing technologies, understanding the fundamentals of blow molding is essential.

Key Benefits of Blow Molding

- High Production Efficiency: Blow molding machines can produce thousands of identical hollow products per hour, making it ideal for large-scale manufacturing.

- Cost-Effective Manufacturing: The process uses less material and labor compared to other molding methods, resulting in lower per-unit costs—particularly for high-volume runs.

- Design Flexibility: Supports custom shapes, sizes, wall thicknesses, and integrated features such as handles, threads, or logos.

- Material Versatility: Compatible with a wide range of thermoplastics, including PET, HDPE, LDPE, PVC, PP, and more.

- Durability and Strength: Produces lightweight yet robust containers and parts suitable for demanding applications.

- Minimal Secondary Operations: Finished parts typically require little to no post-molding finishing, reducing production time.

Blow Molding Process

The blow molding process involves several precise steps to convert raw plastic materials into finished hollow parts. Initially, thermoplastic resin—such as polyethylene (PE), polypropylene (PP), or polyethylene terephthalate (PET)—is melted and formed into a parison (a tube-like piece of plastic with a hole at one end). The parison is then inserted into a custom-designed mold cavity, which determines the final shape of the product.

At this stage, a blow pin injects compressed air into the parison, causing the molten plastic to expand outward and conform tightly to the interior contours of the mold. Achieving a consistent and uniform wall thickness is critical, as variations can impact the strength, appearance, and performance of the finished product. This is why controlled and constant airflow is essential to producing high-quality blow molded parts.

After the plastic has fully expanded and taken the shape of the mold, the cavity is rapidly cooled—usually through conduction using water channels built into the mold. Once the part has solidified, it is carefully removed from the mold, sometimes with the aid of ejector pins or robotic arms for automation. The entire blow molding cycle typically takes only a few seconds, enabling the production of high volumes of durable plastic components with minimal secondary finishing required.

Want to Learn More About How Blow Molding Works?

Explore our in-depth guides on the blow molding process and discover how different materials and techniques influence product performance, cost, and design flexibility.

Types of Blow Molding Techniques

Blow molding technology encompasses several main types, each suited to specific product requirements and industries. The three most common blow molding techniques are injection blow molding, extrusion blow molding, and stretch blow molding. These methods differ primarily in the way the plastic preform (parison) is created and handled prior to the blowing stage. Understanding these variations helps you select the optimal process for your application—whether you need high precision, fast cycle times, or maximum design flexibility.

- Injection Blow Molding (IBM): Best for small, high-precision bottles and medical containers with tight dimensional tolerances.

- Extrusion Blow Molding (EBM): Ideal for medium- to large-sized containers, automotive parts, and industrial packaging with complex shapes.

- Stretch Blow Molding (SBM): Preferred for producing high-clarity PET bottles, especially for food and beverage packaging.

Injection Blow Molding

Injection blow molding is a two-step process combining injection molding and blow molding into a seamless workflow. First, a plastic preform—often referred to as a parison—is injection molded in a precision cavity. The preform is automatically transferred, while still hot, onto a core rod and transported to the blow mold station. Compressed air is introduced through the core rod, expanding the preform to the shape of the blow mold. After cooling, the finished bottle or container is stripped from the core rod, and the process repeats.

Applications: Injection blow molding is commonly used to manufacture small, high-precision containers such as pharmaceutical bottles, cosmetic packaging, personal care products, and medical device housings. The process delivers excellent surface finish, high dimensional accuracy, and uniform wall thickness—making it ideal for products where appearance and tight tolerances are critical.

Key Advantages:

- Superior surface quality and clarity

- Excellent repeatability and control over product dimensions

- Minimal flash and waste material

- Efficient for large-scale, automated production

Extrusion Blow Molding

In extrusion blow molding, plastic pellets are fed through a hopper into a heated barrel, where they are melted and pushed by a screw through a die head to form a continuous hollow tube (parison). Gravity allows the parison to hang vertically until it reaches the desired length, at which point the mold closes around it and seals the bottom. A blow pin is then inserted at the top, inflating the parison to the shape of the mold. The product is cooled, ejected, and trimmed to remove excess material.

Applications: Extrusion blow molding is widely used for making medium- to large-sized containers, such as milk jugs, industrial drums, automotive ducts, fuel tanks, toys, and recreational equipment. Its flexibility allows for the production of containers with handles, integrated spouts, and complex cross-sections.

Key Advantages:

- Accommodates a wide range of sizes and shapes

- Ideal for producing parts with handles or integrated features

- Cost-effective for high-volume production

- Rapid cycle times and minimal tooling costs

Injection Stretch Blow Molding

Injection stretch blow molding (ISBM) is a hybrid process that combines the benefits of injection and blow molding with an additional stretching phase. First, a preform is injection molded using a hot runner system, with the inner and outer diameters defined by a core pin and cavity, respectively. The preform is then cooled, reheated to the optimal temperature, and transferred into a blow mold cavity. Here, it is mechanically stretched lengthwise by a stretch rod while compressed air expands it circumferentially—resulting in a highly oriented, transparent, and impact-resistant final product.

Applications: ISBM is the preferred technology for manufacturing high-clarity, lightweight PET bottles used in the beverage, food, and personal care industries. It is also used for producing pharmaceutical containers, sports bottles, and other packaging that requires excellent barrier properties, optical clarity, and impact resistance.

Key Advantages:

- Produces lightweight bottles with superior strength and clarity

- Excellent for applications requiring high barrier properties (e.g., carbonated beverages)

- Supports custom bottle designs and branding

- Efficient for high-speed, automated production lines

Comparing Blow Molding to Other Plastic Forming Processes

When evaluating blow molding against other manufacturing methods, such as injection molding, rotational molding, thermoforming, and compression molding, it's important to consider your specific part geometry, production volumes, material requirements, and cost constraints. Blow molding excels at producing seamless, hollow components with uniform wall thickness, and is often the only practical choice for bottles, tanks, and similar products.

Key Differences:

- Injection Molding: Best for solid parts; not suitable for hollow objects without complex core-pulling mechanisms.

- Rotational Molding: Used for very large hollow parts (e.g., tanks), but has slower cycle times and less dimensional control.

- Thermoforming: Ideal for shallow, open parts but not true hollow containers.

- Compression Molding: Suited to thermoset plastics and composites, less common for hollow parts.

Interested in comparing blow molding vs. injection molding for your project? See our detailed guide to help you choose the right plastic manufacturing process for your needs.

Blow Molding Materials: Selecting the Right Plastic Resin

Material selection plays a crucial role in blow molding, affecting product performance, cost, recyclability, and regulatory compliance. Common blow molding resins include:

- Polyethylene Terephthalate (PET): High clarity, strength, and barrier properties; used for beverage bottles and food packaging.

- High-Density Polyethylene (HDPE): Excellent chemical resistance and durability; ideal for industrial containers, detergent bottles, and automotive parts.

- Low-Density Polyethylene (LDPE): Flexible and impact-resistant; suitable for squeeze bottles and packaging.

- Polypropylene (PP): Good heat resistance and toughness; used for medical containers and food storage.

- Polyvinyl Chloride (PVC): Chemical and weather resistance; used for specialty bottles and industrial applications.

Need help choosing the right material for your blow molding project? Contact leading blow molding manufacturers to discuss your requirements and request material samples.

Applications and Industries Using Blow Molding

Blow molding is a cornerstone technology for a diverse range of industries and applications. If you are searching for blow molded product examples, evaluating the suitability of blow molding for your specific project, or seeking inspiration for new applications, here are some of the most common uses:

- Beverage and Food Packaging: Water bottles, juice containers, dairy bottles, condiment bottles, and food storage containers.

- Household and Personal Care Products: Detergent bottles, shampoo and lotion containers, cleaning product packaging.

- Medical and Pharmaceutical: Sterile bottles, specimen containers, inhaler housings, and medical device packaging.

- Automotive and Industrial: Fuel tanks, overflow bottles, air ducts, tool housings, and industrial drums.

- Recreation and Toys: Play equipment, sports bottles, outdoor furniture, and floats.

- Construction and Agriculture: Chemical tanks, irrigation pipes, and large storage bins.

Blow molding’s adaptability makes it an ideal manufacturing process for both commodity and specialty products. Businesses looking to innovate packaging, improve part performance, or reduce manufacturing costs frequently turn to custom blow molding solutions tailored to their market needs.

How to Choose the Right Blow Molding Manufacturer

Selecting a reliable blow molding partner is essential for ensuring product quality, cost control, and on-time delivery. When purchasing blow molded products or seeking a partner for custom blow molding projects, it is recommended to compare at least five or six manufacturers. Use our curated list of blow molding manufacturers to efficiently evaluate your options.

- Review each manufacturer’s business profile for details on technical capabilities, certifications (such as ISO or FDA compliance), and industry experience.

- Examine their product galleries or case studies to assess expertise with your target application or market sector.

- Use the integrated RFQ (request for quote) form to contact multiple blow molding suppliers simultaneously, streamlining your sourcing process.

- Take advantage of our patented website previewer to quickly compare manufacturer websites and services before making direct inquiries.

- Consider factors such as lead time, minimum order quantities, tooling costs, secondary services (printing, assembly, packaging), and customer support responsiveness.

Questions to Ask When Evaluating Blow Molding Companies:

- What types of blow molding processes and materials do you specialize in?

- Can you provide samples or prototypes before full-scale production?

- What are your quality assurance and testing protocols?

- Do you offer design assistance or value engineering services?

- How do you handle logistics, shipping, and after-sales support?

Choosing the right blow molding company—whether for stock or custom products—directly impacts your product’s performance, regulatory compliance, and overall project success. For more tips on sourcing, read our manufacturer selection guide.

Frequently Asked Questions About Blow Molding

- What are the main advantages of blow molding over other plastic forming processes?

Blow molding is highly efficient for producing hollow parts, offers cost savings for large volumes, supports complex geometries, and delivers excellent mechanical properties for a wide range of industries. - What is the difference between extrusion and injection blow molding?

Extrusion blow molding is best for larger, more complex shapes and handles, while injection blow molding is preferred for small, high-precision containers and bottles. - Which materials are best suited for blow molding?

PET, HDPE, LDPE, PP, and PVC are the most common, each offering unique advantages for different product requirements. - How can I reduce costs on my blow molded parts?

Optimize part design, select cost-effective materials, increase production volumes, and work with experienced blow molding manufacturers who offer in-house tooling and value-added services. - Can blow molding be used for custom or low-volume production?

Yes, many manufacturers offer custom and short-run blow molding services, though tooling costs and economies of scale should be considered.

Ready to Start Your Blow Molding Project?

Whether you're developing a new packaging solution, redesigning an industrial component, or scaling up production of consumer goods, blow molding provides the manufacturing flexibility, quality, and cost efficiency you need. Use our directory of top blow molding companies to get quotes, request samples, and connect with industry leaders specializing in your market.

Still have questions? Contact our experts for personalized guidance on materials, design, or selecting the right blow molding process for your next project.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

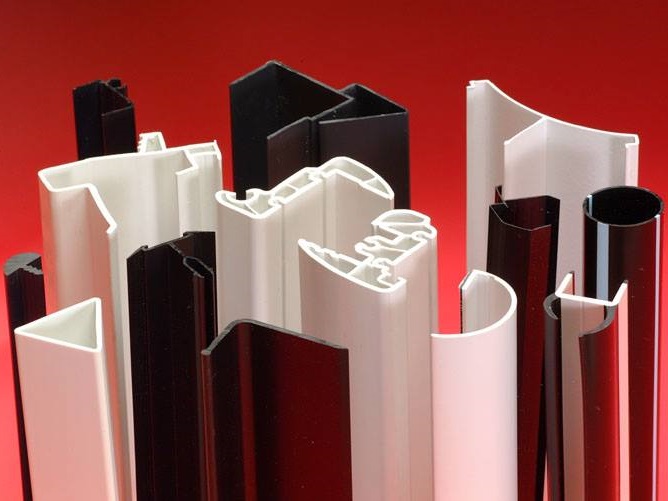

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services