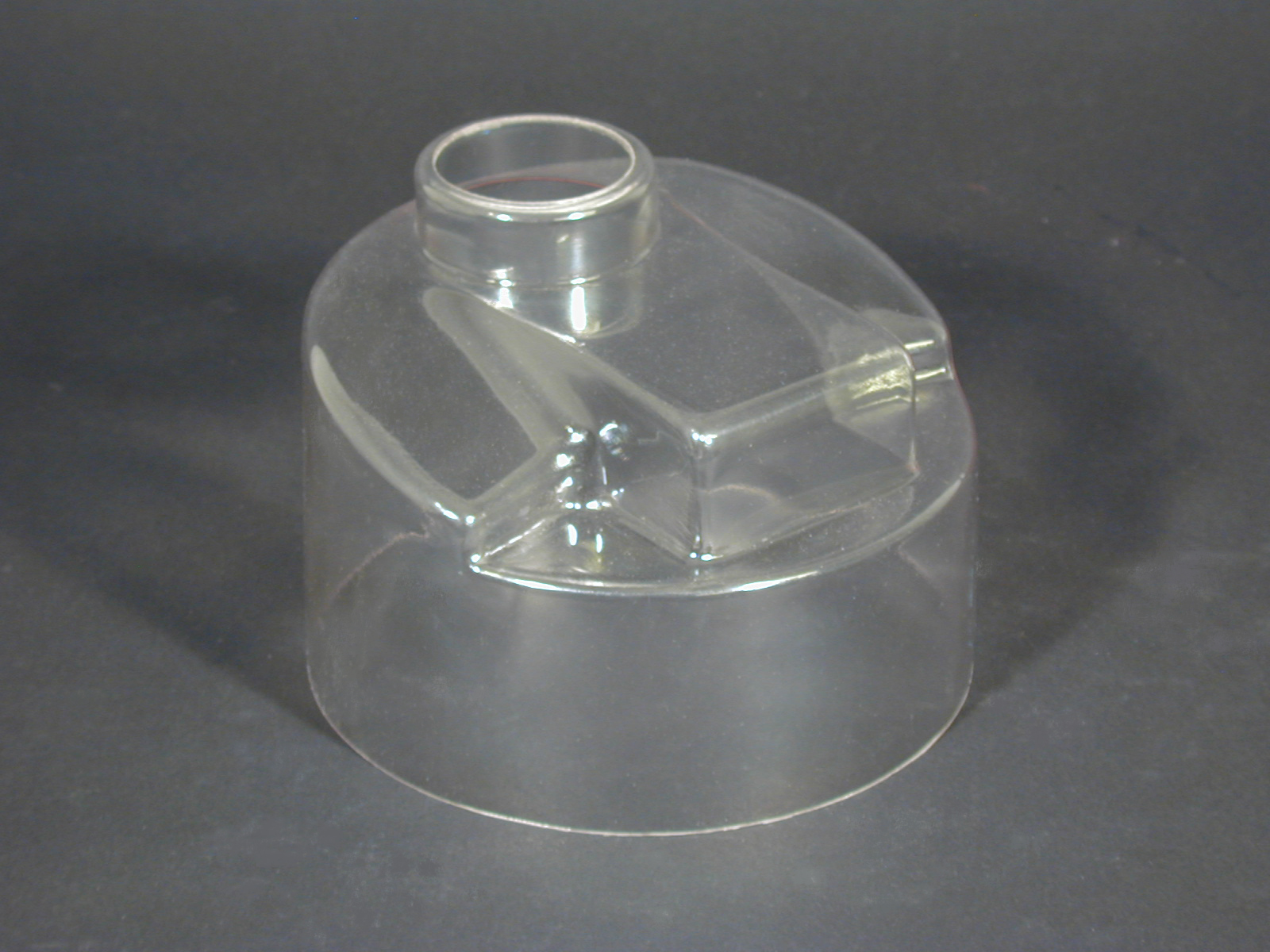

Plastic blow molding is the process of blowing air into a machine to change the shape of plastic. Often, blow molding is combined with the use of molds to create intricate shapes made with thin, hollow plastic pieces. Plastic blow molding did not exist until the late 1930s when a pair of inventors realized the potential for blow molding in the world of plastics.

In 1938, two inventors, Enoch Ferngren and William Kopitke, thought of a way to use the principles of glass blowing in the plastics industry. They created the first plastic blow molding machine and sold it to the Hartford Empire Company. Throughout the 1940s, plastic blow molding was still a new art, and not many companies used the machines because plastic was such a new material at the time.

It was not until the 1970s that plastic blow molding really took off. The plastic soda container was one of the first products to utilize the potential of plastic blow molding fully. Once this process was discovered, blow molding manufacturers popped up all over the United States and the world. Blow molding was used to quickly shape the bottles used for soda storage, including small individual serving bottles and the larger 2 and 3 liter bottles. In fact, soda plastic bottle production was so successful that the amount of plastic soda bottles in production grew from zero to over 10 billion in just 20 years.

Today, blow molded plastic has uses for many different plastic products, including soda bottles, dairy containers, shampoo bottles, hoses, industrial drums, jars, and many other plastic objects and containers. The use of blow molding has not only cut down on the production time for many plastic products, but also plastic waste, due to the small amount of plastic waste created in the molding process.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

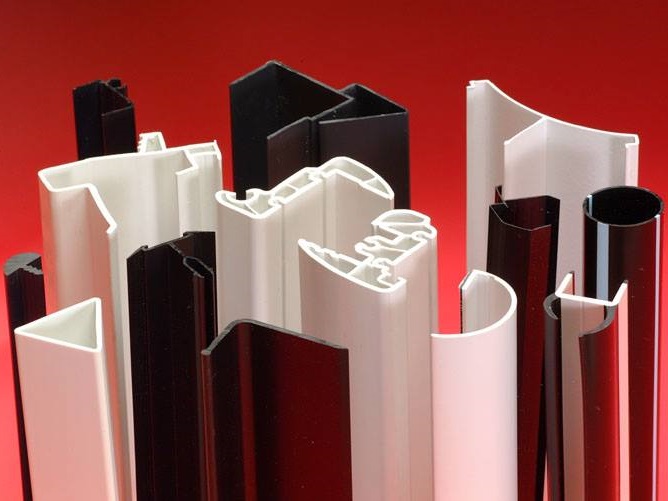

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services