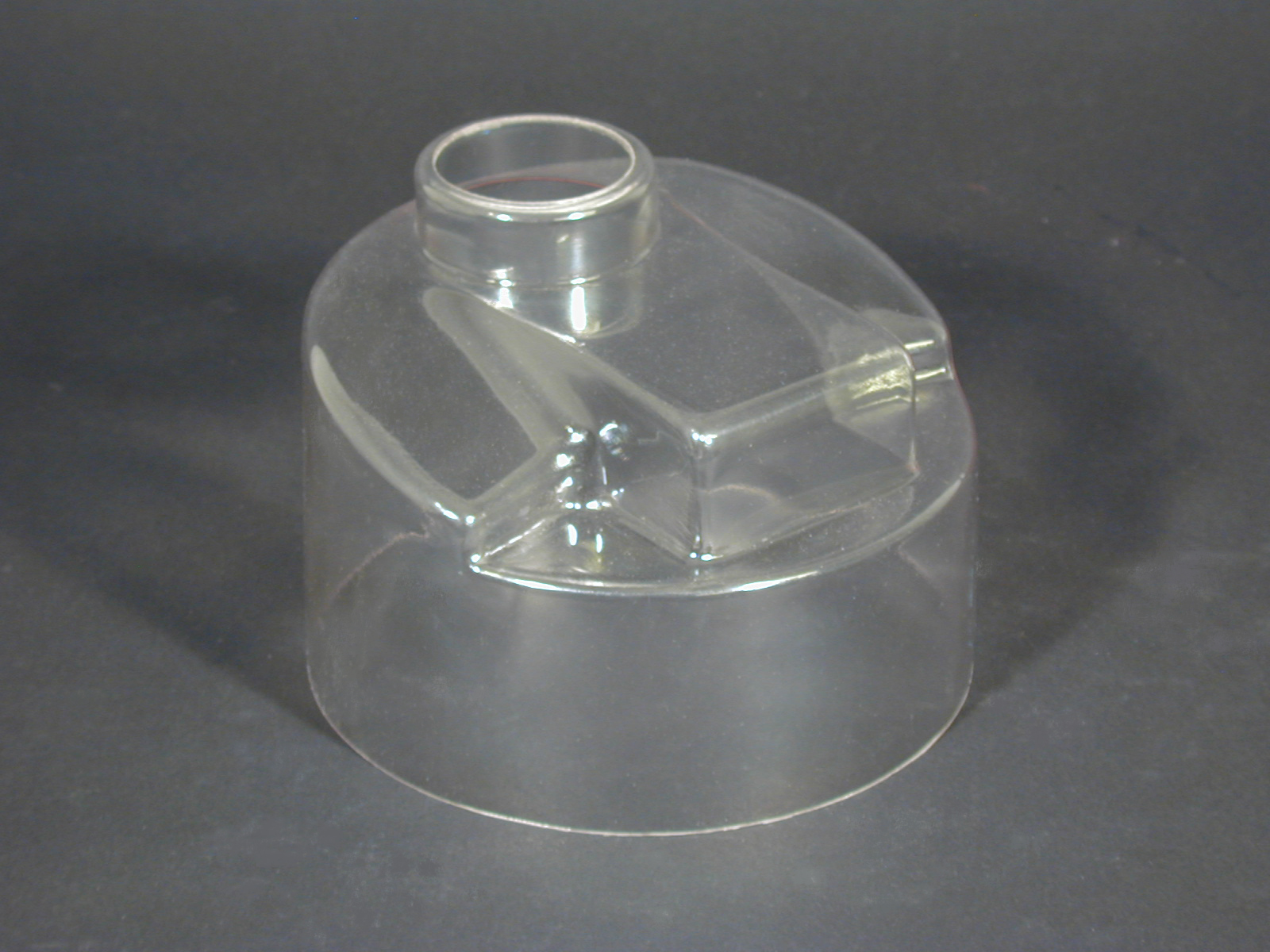

A plastic bottle is a plastic container with a neck that is narrower than the body, one that can hold a specific amount of fluid. and can then be closed with a screw cap, a snap cap, or another sort of closure. Read More…

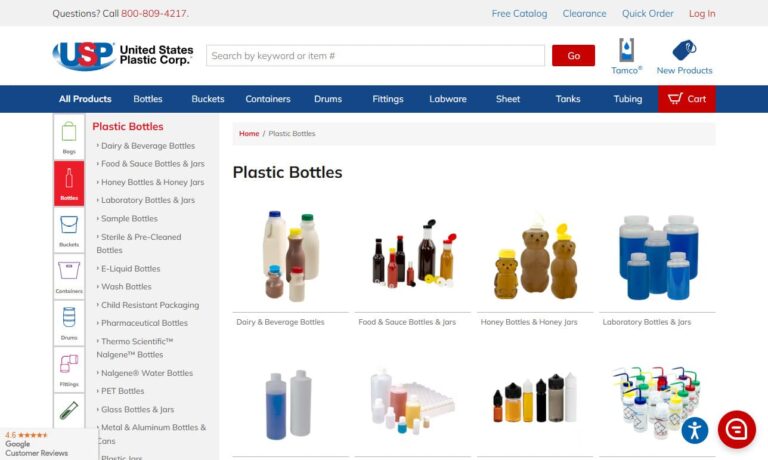

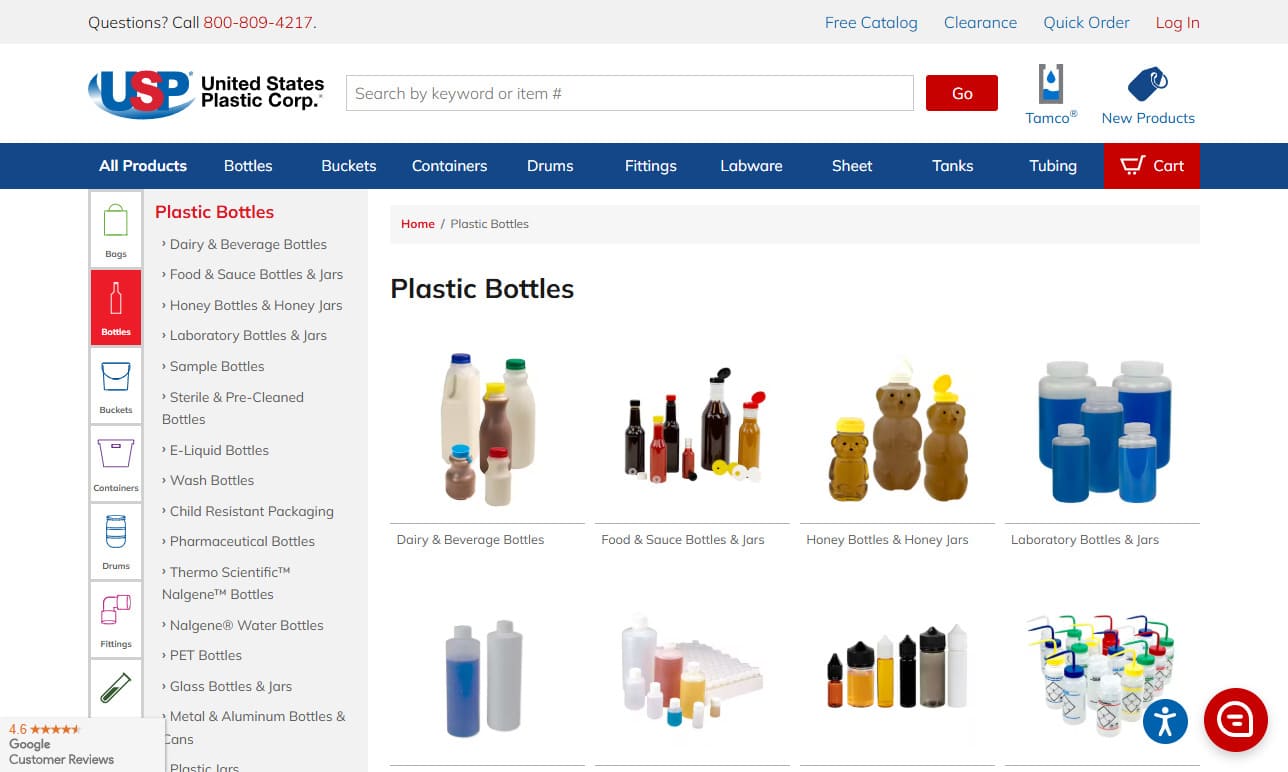

United States Plastic Corp. manufactures and distributes some 25,000 plastic items serving over 85,000 clients operating in a factory five acres under roof. Our major product is manufacturing plastic tanks, the distribution of bottles, carboy and plastic containers. This also includes plastic sheet, rods, tubes, flexible tubing and thousands of plastic fittings.

At Lerner Molded Plastics, we specialize in crafting high-quality blow molded products tailored to meet the diverse needs of our clients. With years of expertise in the industry, we take pride in our ability to deliver innovative solutions that exceed expectations.. For more information about our capabilities, contact us today!

With blow molding presses from 1 to 80 lbs., Iceberg Molding has the ability & resources for every step of your blow molding requirements - from a competitive part quote to part & product development support start to finish.

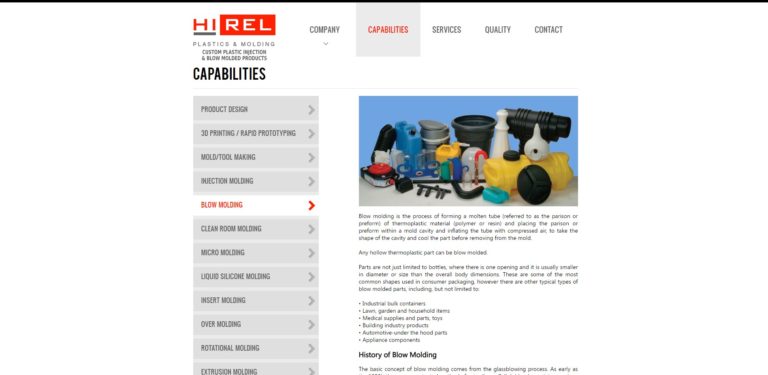

Founded in 1984, Hi-Rel Plastics & Molding, Inc. is a turn-key manufacturer who offers custom blow molding and custom plastic injection molding for a variety of industries. With more than 35 years of experience, our quality products are unparalleled. We process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we offer superior customer...

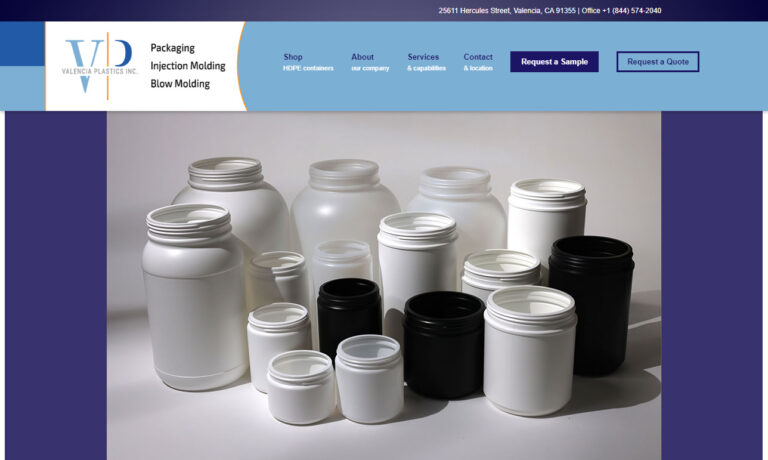

Valencia Plastics is a leading edge blow molder with new methods to add value & ensure superior quality for any job from 10 grams to 3 lbs. Discover our expertise with many plastics & a wide range of machinery. Customers can expect the best from concept to end blow molded plastic product. Industries we serve include aerospace, defense, medical, commercial & pharmaceutical.

Since 1952, SPI Group has provided custom blow molding for a diverse range of industries, such as agricultural, plumbing, electronics, and more. Our team can meet your needs with a variety of plastics, such as HDPE, ABS, polycarbonate, and TPE. Secondary operations and assembly services are also available. SPI is a leader in our industry due to our customer-oriented ability to deliver successful...

EXI-plast is a full-service provider of custom plastic moulding services, specializing in blow moulded solutions for customers worldwide across a wide variety of industries. With over 30 years of experience developing, producing, and finishing custom plastic products, we have also become a sustainability leader through the integration of postconsumer resins. With products ranging from less than...

More Plastic Bottle Companies

What are Plastic Bottles?

Plastic bottles are one of the most popular beverage containers in the modern world. They are made using a process called blow molding. This process enables producers of plastic bottles to create bottles in a wide range of shapes and sizes using a variety of plastic materials.

However, the majority of plastic bottles are often distinguished by their light weight, low price, small diameters, and thin wall construction.

How Plastic Bottles are Made

The different processes in making plastic bottles include:

Extrusion Blow Molding Process

Manufacturers of plastic bottles use an extrusion blow molding technique to generate almost all of their goods in the same way. Manufacturers fill a hopper with stock, which is a collection of tiny, unprocessed thermoplastic pellets or fibers, to begin this process.

They steer the stock away from the hopper and into a conveyance tube with a big screw inside of it. This substantial screw presses the stock while also moving it toward a mold chamber as it rotates. The stock liquefies under the additional impact of heating components in the channel. The plastic is liquefied and then pressed into a mold cavity where it assumes its shape.

The partially-formed plastic product is still inside the mold chamber when manufacturers apply compressed air. The plastic product is made hollow by the compressed air, which is then used to hold it against the mold's body until it resumes its original shape.

The newly-created plastic bottle is then given time to cool and solidify before being taken out of the mold. From here, the product can either be dispatched after being reviewed for flaws or moved on to further processing.

Injection Blow Molding Process

Manufacturers of plastic bottles occasionally produce plastic bottles using injection blow molding (IBM) or injection stretch blow molding.

A molten polymer is delivered into a hot runner manifold during the first stage, where it is then injected via nozzles into a heated cavity and onto a core pin. While the core pin makes sure that the cavity does not solidify and maintains its hollow state, the polymer surrounding the core pin adapts the cavity's shape to create an outside layer. The mold is clamped around a core rod, inflated within a preform, and then chilled at a blow molding station during the second stage of the process.

The finished product is placed in the ejection position and stripped off the core rod during the third stage, which occurs after the plastic form has solidified. It's vital to remember that of all the plastic blow molding methods available, this one is the least frequently used for producing plastic bottles. Instead, it is only applied to the production of tiny bottles and jars.

Additionally, this approach does not allow for the addition of handles or a stronger bottle barrier. The creation of rectangular, cylindrical, and oval bottles is then accomplished via injection stretch blow molding.

There are two ways to perform injection stretch blow molding: one stage or two stages. The preform and the bottle are both blown in the same machine in the first approach. The second approach involves first creating the preforms using the injection molding process, after which they are reheated and stretched into the desired shape. Pressurized air and core rods are used in the final step to assist the preforms expand appropriately.

Materials Used to Make Plastic Bottles

Plastic bottle makers use a variety of plastics, including polyethylene, polyethylene terephthalate (PET), and polypropylene, to create their goods. They might employ recently- produced raw materials or they might use plastics derived from processed and recycled goods.

Since many plastics are harmful to the environment if not recycled, using recycled materials aids firms in lowering their carbon footprint. In keeping with this, numerous plastic bottle producers are also capable of processing discarded plastic bottles for use as recycled material in a mind-boggling array of uses, particularly in the auto sector.

Choosing the Correct Plastic Bottles Manufacturer

To make sure you have the most positive outcome when purchasing Plastic Bottles from a Plastic Bottles Supplier, it is important to compare at least 5 or 6 Companies using our list of Plastic Bottles manufacturers. Each Plastic Bottles Manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each Plastic Bottles company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple Plastic Bottles companies with the same form.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

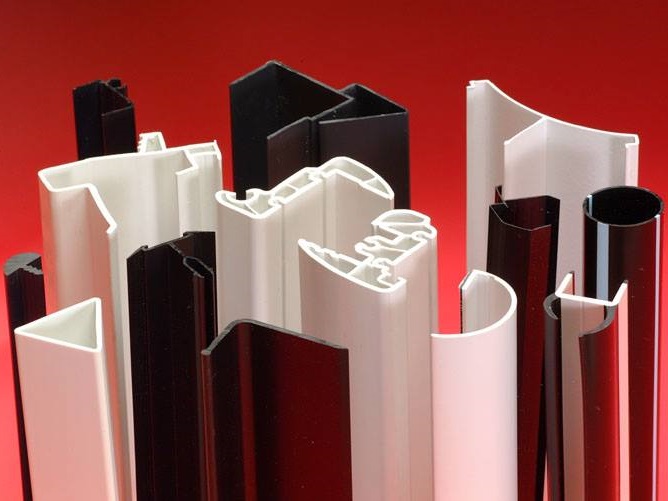

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services