Injection blow molding (IBM) is identical to extrusion blow molding, except that the parison is created around a core rod or metal shank by an injection molding process. The parison comprises a fully formed bottle/jar neck and a thick polymer tube serving as the bottle’s body. Read More…

No matter what your blow molding needs are Western Industries is ready to assist you. We believe in thinking outside the mold and using unique methods to come up with large-part blow molding solutions for our customers. We have access to state-of-the-art technology and over 100 years of combined experience serving a variety of industries. When you choose Western Industries, you have the Western...

With blow molding presses from 1 to 80 lbs., Iceberg Molding has the ability & resources for every step of your blow molding requirements - from a competitive part quote to part & product development support start to finish.

Founded in 1984, Hi-Rel Plastics & Molding, Inc. is a turn-key manufacturer who offers custom blow molding and custom plastic injection molding for a variety of industries. With more than 35 years of experience, our quality products are unparalleled. We process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we offer superior customer...

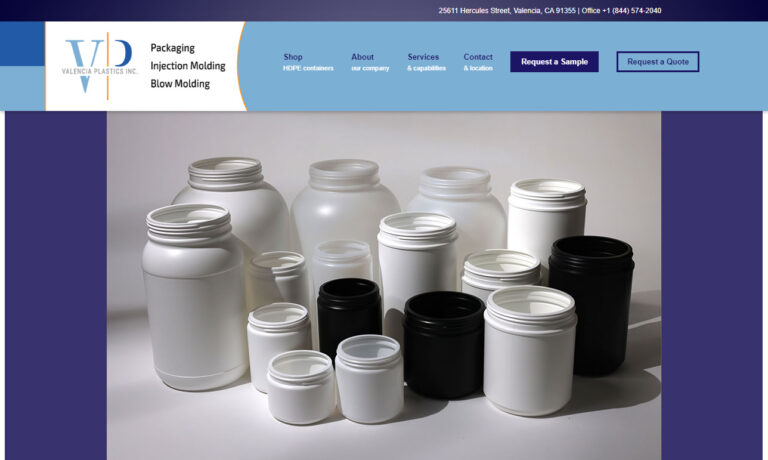

Valencia Plastics is a leading edge blow molder with new methods to add value & ensure superior quality for any job from 10 grams to 3 lbs. Discover our expertise with many plastics & a wide range of machinery. Customers can expect the best from concept to end blow molded plastic product. Industries we serve include aerospace, defense, medical, commercial & pharmaceutical.

Depend on the custom blow molders since 1978. ACM Plastic Products offers complete blow molding capabilities, including many specialty services like insert molding, painting, foaming, assembly & packaging – just name it! New product development & short runs through high volume production, our seasoned professionals put quality & cost efficiency first. Call us today for honestly the best...

EXI-plast is a full-service provider of custom plastic moulding services, specializing in blow moulded solutions for customers worldwide across a wide variety of industries. With over 30 years of experience developing, producing, and finishing custom plastic products, we have also become a sustainability leader through the integration of postconsumer resins. With products ranging from less than...

Since 1952, SPI Group has provided custom blow molding for a diverse range of industries, such as agricultural, plumbing, electronics, and more. Our team can meet your needs with a variety of plastics, such as HDPE, ABS, polycarbonate, and TPE. Secondary operations and assembly services are also available. SPI is a leader in our industry due to our customer-oriented ability to deliver successful...

At Cado Company, we specialize in delivering high-quality blow molding solutions tailored to meet the unique needs of our clients. With years of experience in the industry, we have honed our expertise in producing durable, precise, and reliable blow-molded products.

At Western Case Incorporated, we focus on excellence in blow molding, producing custom plastic cases and components that are designed with precision and durability in mind. Our process allows us to create strong, lightweight products that combine functionality with consistent quality.

More Injection Blow Molding Companies

What is Injection Blow Molding?

Injection blow molding is an advanced plastic manufacturing process that merges elements of both injection molding and blow molding technologies. The process begins by injection molding a preform, also known as a parison, which is then transferred to a blow mold where it is inflated into its final shape. This dual-stage approach requires two separate molds: one for creating the preform and another for shaping the finished product.

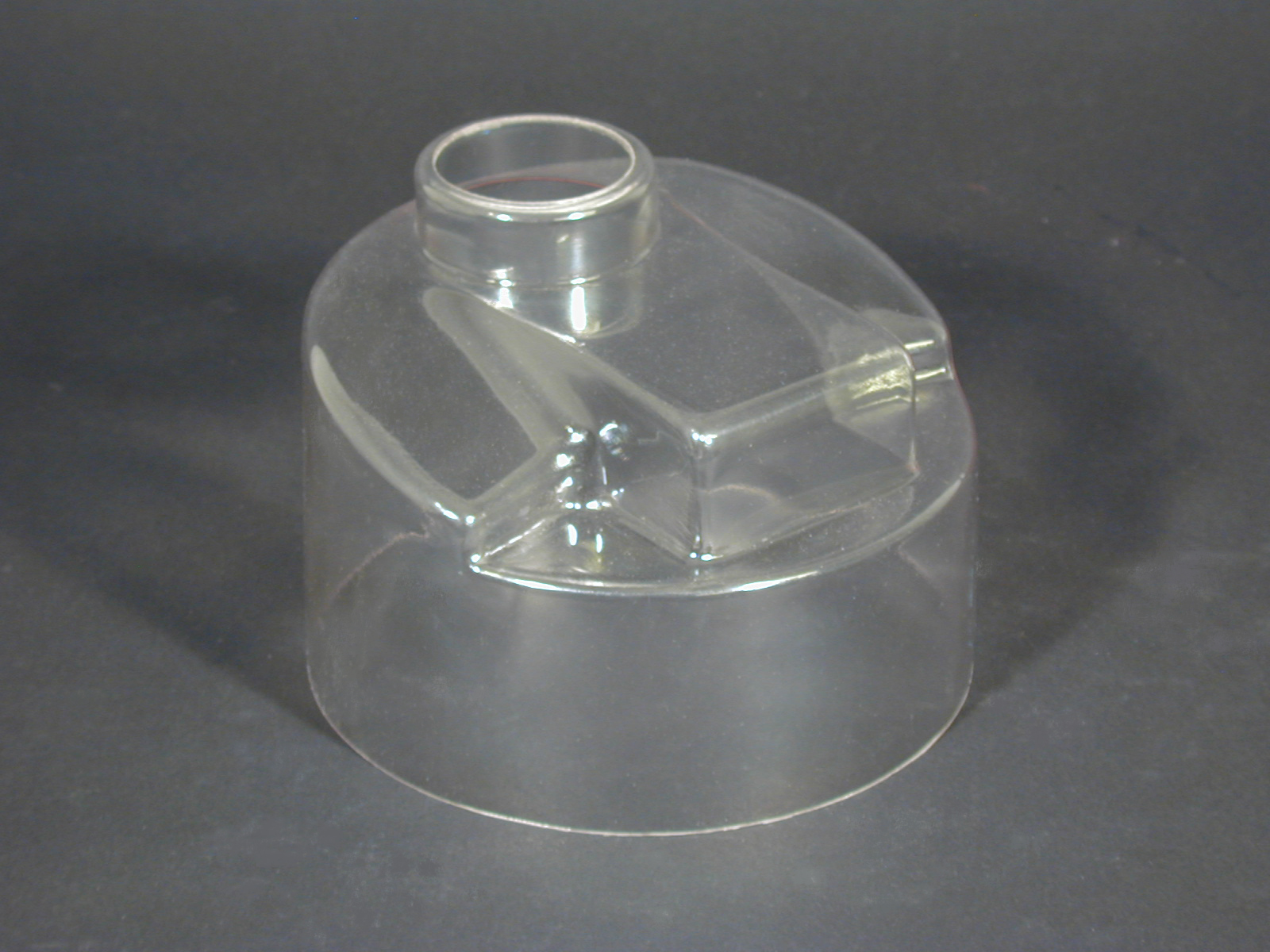

Injection blow molding is widely recognized in the plastics industry for its ability to produce high-quality, dimensionally accurate hollow objects. It’s the process of choice for the mass production of plastic bottles, jars, vials, and other containers used in diverse sectors such as food and beverage, pharmaceuticals, personal care, household chemicals, and industrial packaging. Compared to extrusion blow molding, injection blow molding offers superior control over wall thickness, material distribution, and precision, resulting in products with enhanced aesthetics and performance.

Key Features of Injection Blow Molding

- Delivers exceptional dimensional consistency and tight tolerances

- Produces seamless, flash-free containers with smooth finishes

- Ideal for manufacturing lightweight, high-strength plastic bottles and jars

- Supports a wide range of thermoplastics, including PET, HDPE, LDPE, PP, PVC, and polycarbonate

- Efficient for high-volume production with short cycle times

Popular Applications

- Pharmaceutical vials, droppers, and ampoules

- Cosmetic containers, lotion bottles, and deodorant sticks

- Food and beverage packaging, such as water bottles, juice bottles, and condiment containers

- Household chemical bottles, cleaning product containers, and automotive fluids packaging

- Industrial packaging and laboratory sample containers

How Does Injection Blow Molding Differ from Other Technologies?

If you’re comparing injection blow molding vs. extrusion blow molding or stretch blow molding, consider the key differentiators. Injection blow molding excels when container appearance, neck finish, uniform wall thickness, and dimensional accuracy are critical. This makes it especially valuable for pharmaceutical, cosmetic, and premium food packaging applications, where consistency and quality directly impact product perception.

Injection Blow Molding Process

The injection blow molding process is a sophisticated, multi-stage technique that combines the benefits of injection molding’s precision with the efficiency of blow molding for hollow plastic parts. Here’s a detailed breakdown of the standard process steps:

- Injection Molding of the Preform (Parison): Thermoplastic resin (such as PET, HDPE, PP, or PVC) is heated to its molten state and injected into a preform mold around a core rod or blow stem. This creates a precise, tubular preform with a finished neck and thread detail.

- Transfer to Blow Mold: The preform, still positioned on the core rod, is indexed or rotated into the blow mold cavity. The core rod helps maintain proper alignment and ensures dimensional accuracy.

- Blow Molding Step: Compressed air is introduced through the hollow core rod, inflating the preform like a balloon. The softened plastic expands and conforms tightly to the walls of the blow mold, creating the final container shape with consistent wall thickness.

- Cooling and Ejection: The molded container is cooled within the blow mold, solidifying its shape. Once adequately cooled, the part is ejected—often requiring minimal or no secondary finishing, thanks to the flash-free process.

Did you know? Modern injection blow molding machines often feature multiple core rods and multi-cavity molds, allowing simultaneous production of several containers for maximum efficiency. This makes the process particularly attractive for high-volume runs and custom bottle manufacturing.

Materials Used in Injection Blow Molding

- Polyethylene Terephthalate (PET): Widely used for beverage bottles, food packaging, and pharmaceutical containers due to its clarity, strength, and barrier properties.

- High-Density Polyethylene (HDPE): Popular for milk jugs, detergent bottles, and personal care packaging for its toughness and chemical resistance.

- Low-Density Polyethylene (LDPE): Chosen for its flexibility and squeezability, often used in cosmetic tubes and specialty containers.

- Polypropylene (PP): Preferred for its heat resistance and suitability for hot-fill applications such as syrup bottles and medical packaging.

- Polyvinyl Chloride (PVC): Used for pharmaceutical and industrial bottles where chemical compatibility is required.

- Polycarbonate (PC): Selected for applications requiring high impact resistance and optical clarity.

Looking to Reduce Production Costs?

Injection blow molding is known for its material efficiency and minimal waste generation. Because there is no trim or flash to remove, you save on labor and material costs, making it a sustainable choice for eco-conscious brands.

Injection Blow Molding Machines

Selecting the right injection blow molding machine is critical to achieving consistent quality and operational efficiency. Advanced IBM machines are engineered for high-speed, automated production, capable of forming complex, precision-molded containers with tight neck finishes and smooth surfaces. Here are key factors to evaluate when choosing equipment for your production needs:

1. Plastifier Capacity

The plastifier (plasticizing unit) must be capable of melting and delivering enough thermoplastic resin to fill all mold cavities at once. High-capacity plastifiers ensure rapid cycle times and prevent delays in multi-cavity production, which is essential for large-scale bottle manufacturing.

2. Clamp Tonnage

Clamp tonnage determines the force required to keep the mold closed during injection and blowing. For plastics like LDPE, HDPE, and PP, typical injection pressures range from 3,000 to 5,000 psi. More demanding materials like PVC, PET, and polycarbonate may require up to 10,000 psi. IBM machines are available with injection clamps from 5 to 180 tons, often using hydraulically actuated systems for optimal force distribution.

3. Cycle Time and Dry Cycle

The dry cycle—the time needed for the mold to open, index, and close—impacts overall productivity. High-performance IBM machines can achieve dry cycles as low as 1.5 seconds, while others may require up to 2.7 seconds. When evaluating suppliers, ask about cycle speed and how automation can optimize throughput for your specific bottle design.

Automation and Customization Options

- Multi-cavity molds: Boost productivity by producing several containers per cycle

- Integrated robotics: Enable automated part handling, packaging, and quality inspection

- Custom mold design: Allows for unique container shapes, branding, and specialized neck finishes

- Quality control systems: Inline sensors and vision systems for defect detection and process monitoring

Considering a New Injection Blow Molding Machine?

If you're researching machines, compare features such as energy efficiency, maintenance requirements, and compatibility with your preferred resins. Many manufacturers offer technical support, training, and preventative maintenance services to ensure optimal uptime and long-term reliability.

Advantages of Injection Blow Molding

- Zero or Minimal Scrap: Thanks to in-mold finishing, most bottles and containers are produced without the need for trimming excess material. This reduces waste and lowers your overall production costs, making the process highly sustainable.

- Superior Material Orientation: The injection phase creates molecular alignment in the preform, resulting in containers with enhanced strength, clarity (for transparent materials like PET and PP), and improved barrier properties.

- Excellent Clarity and Aesthetics: The controlled process and precise mold design yield clear, smooth, and visually appealing bottles, ideal for applications where product appearance is crucial.

- Design Flexibility: Retractable bottom plugs and custom mold inserts allow for innovative base designs, ergonomic shapes, and branded features to differentiate your packaging in the market.

- High Dimensional Accuracy: Injection blow molding consistently delivers tight tolerances for neck finishes, threads, and overall container geometry—critical for sealing, capping, and automated filling lines.

- Efficient for Short and Long Runs: The technology supports both small-batch custom projects and high-volume mass production, making it versatile for startups and established brands alike.

- Compatibility with Advanced Resins: The process accommodates a broad spectrum of thermoplastics, enabling tailored solutions for chemical resistance, food safety, and regulatory compliance.

Why Choose Injection Blow Molding Over Other Methods?

Are you comparing injection blow molding vs. extrusion blow molding or stretch blow molding? Injection blow molding stands out for applications demanding precise neck finishes, crystal-clear transparency, and consistent wall thickness. It’s the preferred choice for pharmaceutical bottles, cosmetics, and premium food packaging where quality cannot be compromised.

Common Industries and Use Cases

- Pharmaceutical Packaging: Child-resistant medicine bottles, dropper vials, and single-dose ampoules

- Personal Care: Shampoo bottles, lotion tubes, deodorant sticks, and cosmetic jars

- Food & Beverage: Juice bottles, condiment containers, spice jars, and dairy packaging

- Household & Industrial Chemicals: Detergent bottles, cleaning agent containers, and automotive fluid packaging

- Healthcare & Laboratory: Sample vials, test tubes, and specialized medical containers

What Are the Main Decision Factors When Choosing Injection Blow Molding?

If you're evaluating manufacturing processes for your next packaging project, consider the following criteria:

- Product requirements: Does your application demand tight tolerances, high clarity, or specific barrier properties?

- Material compatibility: Are you working with PET, HDPE, PP, or specialty resins with unique performance needs?

- Production scale: Do you need rapid prototyping, small-batch runs, or high-volume output?

- Design complexity: Are unique shapes, neck finishes, or branding features essential?

- Regulatory standards: Does your product require FDA, USP, or food-grade compliance?

- Cost efficiency and sustainability: Are you seeking to minimize scrap, energy use, and environmental impact?

Choosing the Correct Injection Blow Molding Company

Selecting the right injection blow molding company is a critical step in ensuring your project’s success. Whether you’re launching a new product or scaling existing production, the right manufacturing partner will offer technical expertise, state-of-the-art equipment, and rigorous quality systems to deliver reliable results.

How to Evaluate Injection Blow Molding Suppliers

- Experience and Specialization: Review a supplier’s track record in your industry, their familiarity with your required resin types, and their ability to meet regulatory requirements.

- Technical Capabilities: Assess mold design expertise, in-house tooling, automation integration, and ability to handle complex geometries or tight tolerances.

- Volume Flexibility: Can the manufacturer handle both small custom runs and large-scale orders?

- Quality Assurance: Look for ISO 9001, ISO 13485, or other relevant certifications. Ask about in-process checks, documentation, and traceability systems.

- Customer Support: Do they offer responsive communication, design assistance, and after-sales support?

- Sustainability Initiatives: Consider suppliers with environmentally friendly practices, recycled resin options, and waste reduction programs.

To make sure you have the most constructive outcome when purchasing injection blow molding services, compare at least 6 manufacturers using our comprehensive Injection Blow Molding directory. Each manufacturer’s profile highlights their areas of expertise, capabilities, certifications, and includes a contact form for direct communication. Use our patented website previewer to quickly review company offerings, and leverage our simple RFQ form to request quotes from multiple suppliers with a single submission.

Ready to Request a Quote or Learn More?

Start your search:>Browse injection blow molding companies by specialty, location, or material expertise.

Ask an expert: Need help choosing the right process or resin? Contact us for technical guidance.

Get a quote: Use our simple RFQ form to compare pricing and turnaround times from top manufacturers.

Frequently Asked Questions About Injection Blow Molding

What types of plastic resins can be used in injection blow molding?

Most thermoplastic resins are compatible, including PET, HDPE, LDPE, PP, PVC, and polycarbonate. Material selection depends on your product’s performance, clarity, and chemical resistance needs.

How does injection blow molding improve product quality?

The process delivers precise control over container geometry, wall thickness, and surface finish, resulting in leak-proof, visually appealing bottles with reliable neck finishes for secure closures.

Is injection blow molding cost-effective for small production runs?

While traditionally used for high-volume manufacturing, advancements in machine automation and modular mold design now make it viable for smaller custom runs, prototypes, and pilot projects.

Can I customize bottle shapes and finishes with injection blow molding?

Yes. The process supports custom mold inserts, branded details, ergonomic designs, and specialty neck finishes, enabling unique packaging that stands out on the shelf.

What are the lead times for tooling and production?

Tooling times vary based on design complexity, but rapid prototyping and digital mold design can significantly reduce development cycles. Production lead times depend on order size, machine availability, and material selection.

How do I ensure regulatory compliance for food, pharma, or medical packaging?

Work with suppliers experienced in FDA, USP, or ISO-compliant manufacturing. Specify material traceability and documentation requirements upfront for full compliance.

Still Have Questions?

Search our knowledge base: Find answers to common injection blow molding questions.

Explore related processes: Extrusion blow molding, general blow molding, and more.

Contact our experts: Reach out for personalized advice on your next project.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

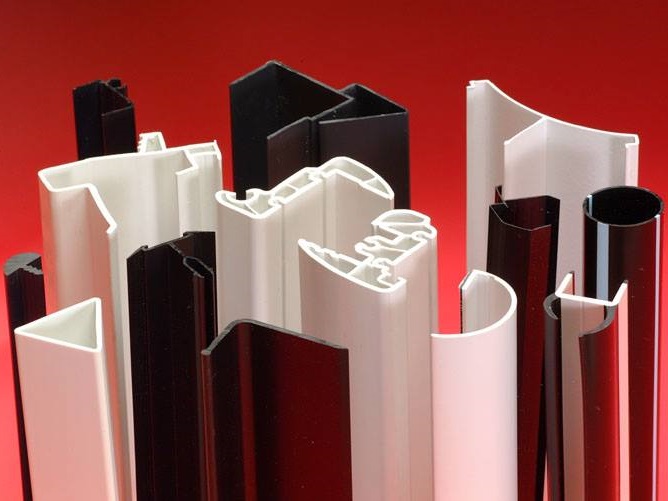

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services