Extrusion blow molding bottles are made to hold beverages like juice and pop, liquid soap, detergent, and motor oil for consumer and industrial applications within the food and beverage, automotive, cleaning products, medical, cosmetics, and drinking water industries. Read More…

No matter what your blow molding needs are Western Industries is ready to assist you. We believe in thinking outside the mold and using unique methods to come up with large-part blow molding solutions for our customers. We have access to state-of-the-art technology and over 100 years of combined experience serving a variety of industries. When you choose Western Industries, you have the Western...

With blow molding presses from 1 to 80 lbs., Iceberg Molding has the ability & resources for every step of your blow molding requirements - from a competitive part quote to part & product development support start to finish.

Founded in 1984, Hi-Rel Plastics & Molding, Inc. is a turn-key manufacturer who offers custom blow molding and custom plastic injection molding for a variety of industries. With more than 35 years of experience, our quality products are unparalleled. We process an almost infinite variety of thermoplastic resins, our prices are competitive, our delivery is on time, and we offer superior customer...

Valencia Plastics is a leading edge blow molder with new methods to add value & ensure superior quality for any job from 10 grams to 3 lbs. Discover our expertise with many plastics & a wide range of machinery. Customers can expect the best from concept to end blow molded plastic product. Industries we serve include aerospace, defense, medical, commercial & pharmaceutical.

Depend on the custom blow molders since 1978. ACM Plastic Products offers complete blow molding capabilities, including many specialty services like insert molding, painting, foaming, assembly & packaging – just name it! New product development & short runs through high volume production, our seasoned professionals put quality & cost efficiency first. Call us today for honestly the best...

EXI-plast is a full-service provider of custom plastic moulding services, specializing in blow moulded solutions for customers worldwide across a wide variety of industries. With over 30 years of experience developing, producing, and finishing custom plastic products, we have also become a sustainability leader through the integration of postconsumer resins. With products ranging from less than...

Since 1952, SPI Group has provided custom blow molding for a diverse range of industries, such as agricultural, plumbing, electronics, and more. Our team can meet your needs with a variety of plastics, such as HDPE, ABS, polycarbonate, and TPE. Secondary operations and assembly services are also available. SPI is a leader in our industry due to our customer-oriented ability to deliver successful...

At Cado Company, we specialize in delivering high-quality blow molding solutions tailored to meet the unique needs of our clients. With years of experience in the industry, we have honed our expertise in producing durable, precise, and reliable blow-molded products.

At Western Case Incorporated, we focus on excellence in blow molding, producing custom plastic cases and components that are designed with precision and durability in mind. Our process allows us to create strong, lightweight products that combine functionality with consistent quality.

More Extrusion Blow Molding Companies

Complete Guide to Extrusion Blow Molding: Process, Machines, Applications, and Supplier Selection

What is Extrusion Blow Molding?

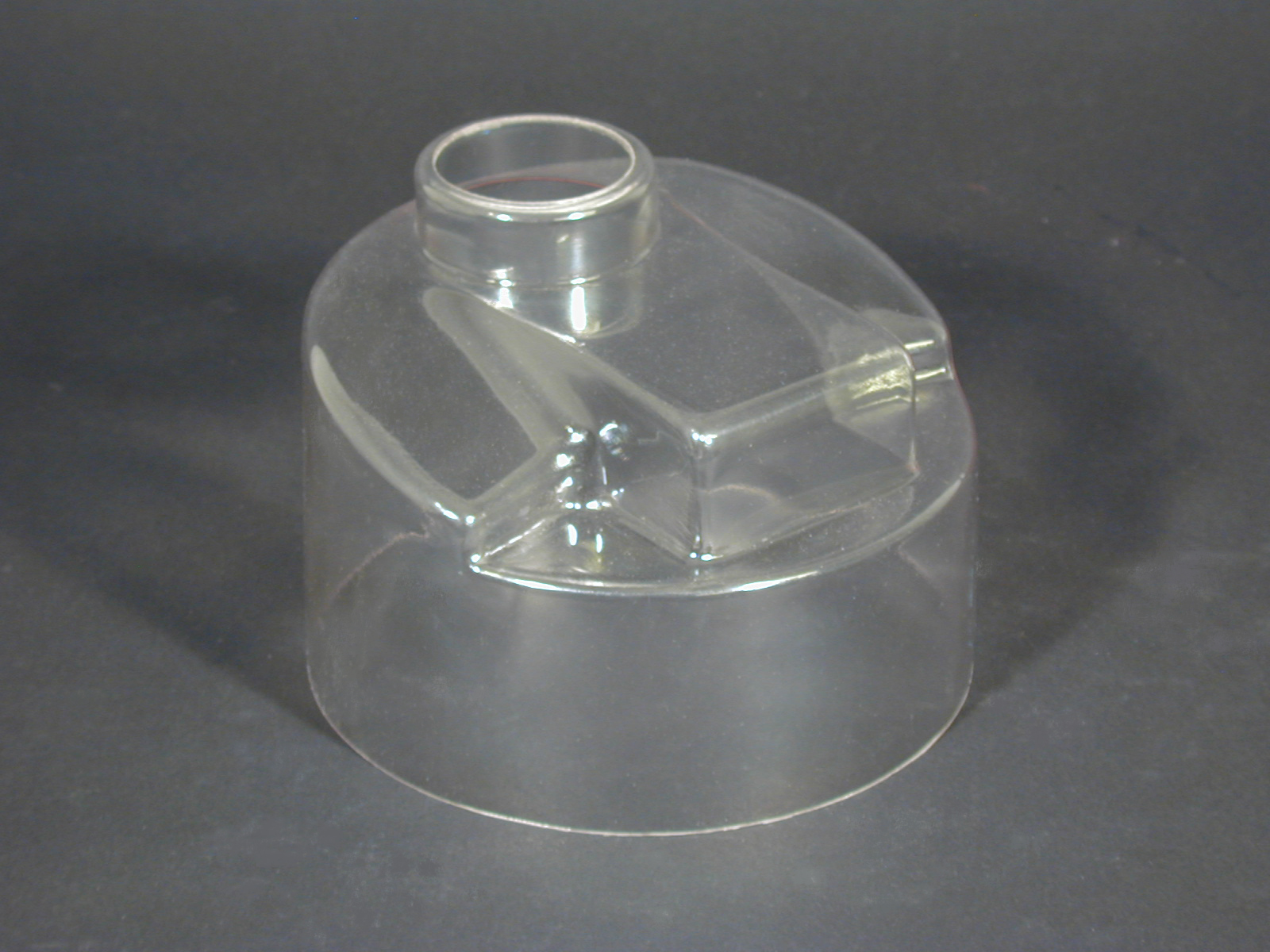

Extrusion blow molding is a widely used plastic manufacturing process that creates hollow plastic parts and containers efficiently. In this method, plastic is heated and extruded into a molten tube called a parison. The parison is then enclosed in a set of mirror-image molds, and compressed air is used to inflate the parison, pressing it against the mold walls to form the desired shape. This results in products with a visible seam dividing the finished part, such as a plastic bottle, in half. Unlike other blow molding processes, extrusion blow molding (EBM) produces minimal waste, and all scrap is fully recyclable, supporting sustainability objectives.

A defining feature of extrusion blow molding is the hollow tube—known as the parison—extruded from the machine. This method is ideal for high-volume manufacturing of hollow products and containers, especially where design flexibility and cost efficiency are crucial.

How Does the Extrusion Blow Molding Process Work?

The extrusion blow molding process consists of several integrated stages designed to deliver consistent, high-quality plastic products. Here's a step-by-step overview:

- Plastic Melting: Raw plastic pellets—commonly polyethylene (HDPE, LDPE), polypropylene (PP), or PET—are loaded into a hopper and conveyed into an extruder. The extruder screw and barrel, fitted with heating elements, melt the resin into a uniform, viscous form.

- Parison Formation: The molten plastic is forced through a die head, forming a vertically-oriented soft tube called a parison. The size and thickness of the parison are carefully controlled to suit the final product specifications.

- Mold Enclosure: Two halves of a hollow mold close around the parison. The mold's internal cavity matches the final product's shape—such as a bottle, drum, or automotive duct.

- Blowing and Shaping: Compressed air is injected into the parison, inflating it so that it conforms perfectly to the contours of the mold. This step is critical for achieving uniform wall thickness and precise dimensions.

- Cooling: Cold water circulates through the mold to rapidly cool and solidify the newly formed plastic part. This ensures dimensional stability and fast cycle times.

- Part Ejection and Finishing: Once cooled, the mold opens, and the finished part is ejected. Excess material, such as flash along the seam or at the neck, is trimmed in subsequent post-processing steps.

This process is highly efficient, with each cycle taking only a few seconds, making extrusion blow molding ideal for high-volume production runs. The method can be performed in continuous or intermittent cycles, depending on product complexity and production requirements.

Post-Processing and Finishing Operations

After molding, parts often undergo further operations to enhance performance or appearance. Common post-processing techniques include drilling, die cutting, milling, painting, and the application of decals or labels. These finishing steps are essential for products with strict dimensional tolerances or specific branding requirements. The newly formed plastic parts may also be assembled, tested for leaks or strength, and packaged for distribution.

Types of Extrusion Blow Molding Machines

Selecting the right blow molding equipment is crucial for efficient production and optimal product quality. There are two primary categories of extrusion blow molding machines:

- Two-Station (Shuttle) Machines: In these systems, a common mold shuttles back and forth between the extrusion head and the blow station. Shuttle machines offer flexibility and are suitable for small to medium production volumes, or for manufacturing varied product sizes and shapes.

- Continuous (Wheel) Machines: These machines operate with several molds rotating on a wheel, enabling continuous parison extrusion and simultaneous molding of multiple parts. Wheel machines are designed for high-speed, high-volume production, commonly used in industries such as beverage packaging and household products.

Compared to injection blow molding (IBM), extrusion blow molding accommodates larger parts, offers lower tooling costs, and requires less stringent control over internal stresses. However, EBM typically produces more scrap and may provide less precision for critical dimensions.

Materials Used in Extrusion Blow Molding

Choosing the right thermoplastic material is essential for meeting application requirements regarding strength, chemical resistance, clarity, and cost. Common resins used in extrusion blow molding include:

- High-Density Polyethylene (HDPE): Popular for its strength, impact resistance, and suitability for food packaging and industrial containers.

- Low-Density Polyethylene (LDPE): Offers flexibility and is often used for squeeze bottles and soft containers.

- Polypropylene (PP): Known for its chemical resistance and suitability for automotive parts and reusable containers.

- Polyethylene Terephthalate (PET): Used for clear containers, beverage bottles, and food packaging.

- Polyvinyl Chloride (PVC): Utilized in applications requiring transparency and chemical resistance.

- Engineering Plastics: Such as polycarbonate (PC) and nylon, for specialized industrial uses.

Applications and Use Cases for Extrusion Blow Molding

Extrusion blow molding is a versatile process used across a vast range of industries. Its ability to produce lightweight, durable, and cost-effective hollow parts makes it the method of choice for many manufacturers. Common applications include:

- Packaging: Bottles for beverages, cosmetics, personal care, detergents, and household chemicals.

- Industrial Containers: Drums, jerry cans, fuel tanks, and lubricant containers.

- Automotive Components: Ducts, reservoirs, air intake manifolds, and fluid tanks.

- Toys and Recreation: Balls, floats, and play equipment.

- Medical Products: IV containers, pharmaceutical bottles, and laboratory supply bottles.

- Consumer Goods: Watering cans, coolers, storage tanks, and sporting goods.

Industry-Specific Insights

Are you searching for the most efficient packaging solution for your beverage or food brand? Extrusion blow molding is the top choice for high-volume plastic bottle production, ensuring uniform wall thickness, reliability, and fast turnaround. Need durable fuel tanks or automotive fluid reservoirs? The process can handle complex geometries and stringent requirements for chemical resistance and mechanical strength. For OEMs and contract manufacturers, EBM provides scalability and flexibility, accommodating rapid product design changes and short lead times.

Advantages of Extrusion Blow Molding

Extrusion blow molding stands out in the plastic manufacturing industry for its unique combination of speed, flexibility, and cost-effectiveness. Key advantages include:

- Low Tooling Costs: Compared to injection blow molding, EBM requires simpler molds, reducing upfront investment and making it attractive for both startups and established manufacturers.

- High Production Rates: The process supports continuous or intermittent production, enabling rapid output of thousands of units per hour.

- Design Flexibility: EBM accommodates a wide range of product sizes and shapes, including complex geometries and integrated handles.

- Material Efficiency: Minimal waste is generated, and all excess plastic (flash and trim) can be recycled, supporting sustainability goals.

- Capability for Large Parts: Unlike injection blow molding, EBM can produce large hollow parts, such as drums and tanks, at lower cost.

- Seamless Integration of Handles: Unique to EBM, handles can be formed as part of the bottle or container, reducing assembly steps and improving ergonomics.

Comparing Extrusion Blow Molding to Other Processes

When evaluating blow molding methods, it's important to compare EBM to alternatives like injection blow molding (IBM), stretch blow molding (SBM), and rotational molding. EBM offers unbeatable efficiency for high-volume, hollow plastic parts with moderate dimensional tolerance. For applications needing superior clarity or pressure resistance, such as carbonated beverage bottles, stretch blow molding may be preferable. For very large or thick-walled items, rotational molding might be more suitable. Explore the differences in our injection blow molding resource guide.

Disadvantages and Limitations of Extrusion Blow Molding

While EBM is a versatile and cost-effective process, it does have some limitations to consider:

- Wall Thickness Variation: Maintaining uniform wall thickness can be challenging, leading to potential weak spots in finished parts.

- Dimensional Precision: Less control over critical dimensions compared to injection blow molding, making EBM less suitable for highly precise or small parts.

- Scrap Generation: Although recyclable, EBM produces flash and trim waste, especially with complex molds or integrated handles.

- Post-Processing Requirements: Additional finishing steps, such as trimming and drilling, may be necessary, increasing labor and equipment needs.

- Material Limitations: Not all thermoplastics are suitable for EBM, and multi-layer or barrier packaging may require specialized equipment.

Overcoming Common Challenges

Modern advancements in extrusion die design, process automation, and real-time monitoring have helped mitigate many of these issues. For example, parison programming systems enable dynamic control over wall thickness, enhancing consistency and reducing material usage. Are you struggling with off-spec parts or excessive scrap? Consult with your extrusion blow molding supplier about the latest process control technologies and best practices for optimizing output quality.

How to Choose the Right Extrusion Blow Molding Supplier

Finding the ideal extrusion blow molding partner can dramatically impact your product’s quality, cost, and time-to-market. Here’s a step-by-step approach to selecting the best supplier:

- Define Your Requirements: Specify part dimensions, material preferences, production volumes, regulatory standards (e.g., FDA, ISO), and special features (such as handles or multi-layer construction).

- Research Suppliers: Use our curated list of extrusion blow molding companies to identify potential partners. Each supplier profile details their technical expertise, production capabilities, and value-added services.

- Compare Capabilities: Evaluate each supplier’s experience with similar products, equipment inventory (shuttle vs. wheel machines), secondary operations, and quality assurance protocols.

- Request Quotes and Samples: Use our simple RFQ form to contact multiple suppliers simultaneously. Ask for detailed quotations, lead times, and sample parts to assess quality.

- Review References and Certifications: Check customer testimonials, industry certifications, and case studies to verify track record and compliance.

- Assess Communication and Support: Effective collaboration and responsive technical support are essential for successful project execution and ongoing optimization.

To ensure the best outcome when purchasing extrusion blow molded products, compare at least four or five companies. Review each extrusion blow molding business website using our patented website previewer to get a clear idea of their specialization and capabilities. Then, utilize our RFQ form to reach out to multiple companies with a single message, streamlining your supplier search process.

Key Decision Factors for Buyers

- Production capacity and lead times

- Experience with your target industry (packaging, automotive, medical, etc.)

- Material and design flexibility

- In-house tooling and engineering support

- Quality control procedures (in-process inspection, leak testing, certifications)

- Secondary services (assembly, decoration, logistics)

- Environmental and sustainability practices

Frequently Asked Questions About Extrusion Blow Molding

What products are best suited for extrusion blow molding?

EBM excels at manufacturing hollow, seamless plastic parts such as bottles, tanks, containers, and ducts. It is ideal for products requiring lightweight construction, durability, and cost efficiency, especially in food and beverage, industrial, automotive, and consumer goods sectors.

How does extrusion blow molding differ from injection blow molding?

Extrusion blow molding forms a parison that is inflated within a mold, supporting larger parts and integrated handles, while injection blow molding uses a preform injection-molded before being blown. IBM offers greater dimensional accuracy but is typically limited to smaller items.

What materials can be used in extrusion blow molding?

Most thermoplastics can be used, including HDPE, LDPE, PP, PET, PVC, and specialized engineering plastics, depending on the application’s requirements for strength, clarity, and chemical resistance.

How do I reduce scrap in the extrusion blow molding process?

Utilize modern parison programming and trimming technologies, optimize mold design, and work with suppliers who recycle flash and trimmings. Continuous process monitoring also helps reduce waste and improve yield.

What is the typical lead time for custom extrusion blow molded parts?

Lead times vary by project complexity, tooling requirements, and supplier capacity. Standard projects may take a few weeks from design finalization to initial production, while custom tooling and large-scale orders may require longer timelines. Request detailed schedules from your supplier during the quoting phase.

Ready to Start Your Extrusion Blow Molding Project?

Looking for a reliable extrusion blow molding partner for your next packaging, automotive, or industrial application? Contact top-rated suppliers using our comprehensive directory. Not sure which process or material is right for your product? Ask our experts for a tailored consultation. For more information on blow molding processes, materials, and supplier selection, explore our in-depth resource hub or request a quote today.

Conclusion

Extrusion blow molding is a cornerstone of the plastics manufacturing industry, delivering high-quality, cost-effective solutions for countless applications. With its ability to form complex, hollow shapes at scale, EBM is the preferred choice for packaging, automotive, industrial, and consumer product manufacturers worldwide. By understanding the process, applications, material options, and supplier selection criteria, buyers can make informed decisions and achieve exceptional product outcomes. Ready to transform your ideas into reality? Start your extrusion blow molding journey with industry-leading experts and state-of-the-art technology.

Fiberglass Fabricators

Fiberglass Fabricators Injection Molded Plastics

Injection Molded Plastics Plastic Blow Molding

Plastic Blow Molding Plastic Dip Molding

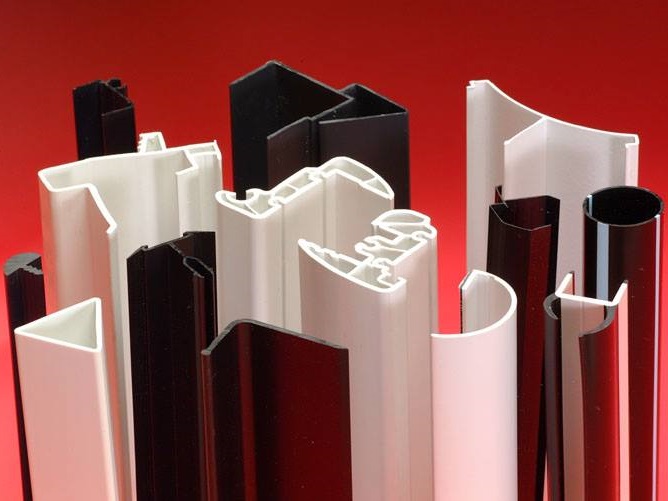

Plastic Dip Molding Plastic Extrusions

Plastic Extrusions Plastic Tubing

Plastic Tubing Polyurethane Molding

Polyurethane Molding Rotational Molding

Rotational Molding Vacuum Forming

Vacuum Forming Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services